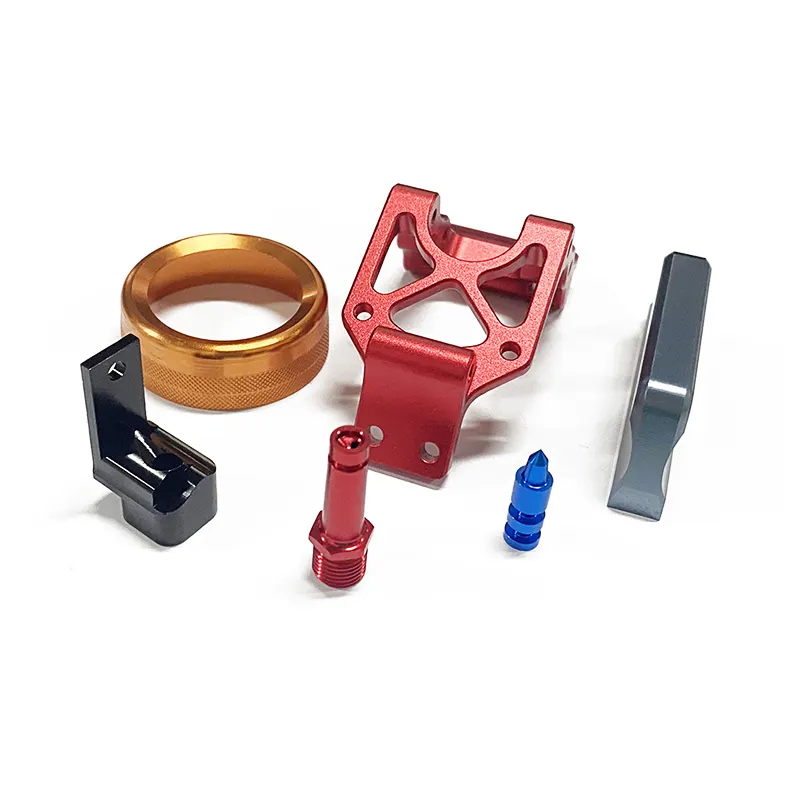

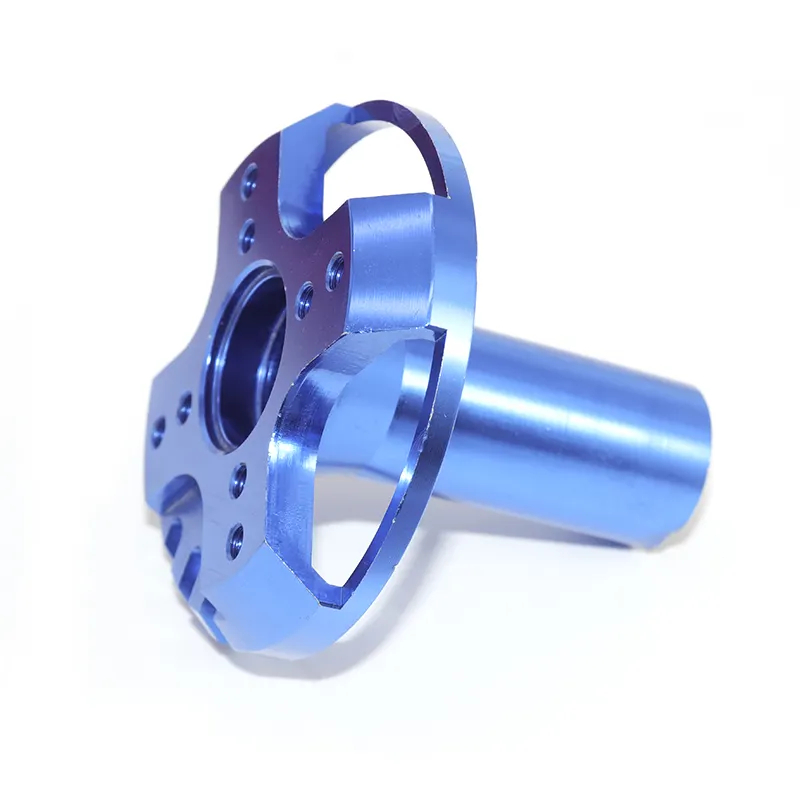

OEM High Precision CNC Machining Chaw Pab

CNC Machining Service

Txheej txheem: CNC Tig, CNC Milling, Tig-Zeb Txuas.

▪ Ib qho kev daws teeb meem rau CNC machining.

▪ Cov qhov chaw kho tshuab, nrum, machined seem, kev cai cnc qhov chaw, prototypes.

▪ Cov chaw tsim khoom siab siab.

At Ua tus muab kev pabcuam zoo CNC MACHINERT.

▪ Customization: Customized logo, customized ntim, cov duab sib txuas.

▪ Khoom siv: Stainless hlau, txhuas, carbon hlau, tooj, tooj liab, tooj dag, hlau alloy, Titanium thiab lwm yam.

| Siab Precision Zoo OEM CNC MACHINING QHOV | |

| Kev pab | CNC Raws, Cnc Milling, Laser Txiav, Dabtsi Yog Khoov, Vuam, Hlau Txiav, Fais Dawb Machining (EDM), Txhaj Tshuaj Molding |

| Ntaub ntawv | Aluminium: 2000 Series, 6000 Series, 7075, 5052, thiab lwm yam. |

| Stainless hlau: Sus304, SS316, SS316, SS316L, 17-4-4-etc. | |

| Hlau: 1214L / 1215/1045/4140 / scm440 / 40crmo, thiab lwm yam. | |

| Tooj dag: 260, C360, H59, H59, H62, H62, H63, H65, H68, H70, tooj liab, tooj | |

| Titanium: Troadef1-F5 | |

| Nto Kho | Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Kev nyiaj tau | +/- 0.002 ~ +/- 0.005mm |

| Nto roughness | Min ra0.1 ~ 3.2 |

| Kos duab txais | STP, kauj ruam, IGS, XT, Autocad (DXF, DWG), PDF, lossis kuaj |

| Lem sij hawm | 1-2 lub lis piam rau kev kuaj, 3-4 lub lis piam rau kev ntau lawm |

| Kev Muaj Peev Xwm Zoo | ISO9001: 2015, ISO13485: 2016, SGS, ROHS, TUV |

| Cov ntsiab lus them nqi | TT / Paypal / Westunion |

OEM CNC Machining Siab Precision Zoo Siab Steel / Steel Chaw

OEM CNC MACHINING muaj khoom zoo tooj thiab titanium seem

Cov Khoom Ntim

Cov FAQ

1. Dab tsi yog cnc machining?

CNC (Khoos phib tawj tswj) yog hom kev sib cav sib ceg. Raws li cov duab kos, CNC siv cov cuab yeej sib txawv los txiav cov khoom siv raw los ntawm lub cajmeem.

2. Kuv yuav tau txais txiaj ntsig dab tsi los ntawm CNC?

Piv rau lwm txoj kev tsim khoom, cnc machining yog ib txoj kev rau cov ntaub ntawv, qhov loj me, tsawg heev ntim ntau lawm. Nws tshwj xeeb yog kev lees paub ruaj khov, precision, thiab zawm thev.

3. Kuv tuaj yeem tau txais cov lus sau tseg li cas?

Cov duab kos duab kom ntxaws (PDF / Kauj Ruam / IGS / DWG ...) nrog cov khoom siv, kom muaj nuj nqis thiab cov ntaub ntawv kho kom muaj nuj nqis.

4. Kuv puas tuaj yeem tau txais cov lus tsocai tsis muaj kev kos duab?

Nco ntsoov, peb txaus siab tau txais koj cov qauv, duab lossis cov ntawv sau nrog cov ncauj lus kom ntxaws rau cov lus hais raug.

5. Kuv yuav kos kuv cov duab puas yog tias koj tau txais txiaj ntsig?

Tsis yog, peb them nyiaj ntau los tiv thaiv peb cov neeg siv khoom tsis pub muaj kev kos duab, kos npe NDA kuj tseem tau txais yog tias xav tau.

6. Koj puas tuaj yeem muab cov qauv ua ntej pawg ntau lawm?

Nco ntsoov, tus nqi kuaj pom tseeb, yuav tau rov qab los ntawm cov loj thaum tsim tau yog tias ua tau.

7. Yuav ua li cas txog lub sijhawm txhuas?

Feem ntau, 1-2 lub lis piam rau cov qauv, 3-4 lub lis piam rau huab hwm coj ntau lawm.

8. Koj tswj tau qhov zoo li cas?

(1) Kev Tshuaj Ntsuam Khoom - Xyuas cov khoom saum npoo av thiab ntxig loj.

(2) Kev Soj Ntsuam Thawj Zaug Zej Zog Ua Ntej - Kom paub tseeb tias qhov tseem ceeb ntawm kev tsim ntau ntau yam.

(3) Ntsuas cov qauv tshuaj xyuas - xyuas qhov ua tau zoo ua ntej xa mus rau lub tsev rau khoom.

(4) Kev Soj Ntsuam Ua Ntej Ua Ntej - 100% tshuaj xyuas los ntawm QC cov neeg pabcuam ua haujlwm ua ntej ua zaub mov xa tuaj.

9. Koj yuav ua li cas yog tias peb tau txais qhov tsis zoo?

Thov ua siab zoo xa cov duab peb, peb cov kws tsim tawm yuav pom cov kev daws teeb meem thiab rov qab ua rau koj asap.